Wet Cast Machinery artificial stone veneer production line

Enquiry Email: harvey_lya@zzlya.com

Product Description 1.wet cast doser dosing machine line equipment for customers to save labor costs, reduce labor, and achieve automation and high-efficiency production. According ŌĆ”ŌĆ”

Introduction

Product Description

1.wet cast doser dosing machine line equipment for customers to save labor costs, reduce labor, and achieve automation and high-efficiency production. According to the driving method, it can be motor-driven, pneumatic, or hydraulically-driven, pneumatic and electric. According to the size of the concrete mold, they design the length and width of the production line, and also the size and quantity of the mold position. According to the concrete mold size, weight, and customer’s production requirements, they design the feeding part, which can be two blanking ports, four blanking ports, or 5 blanking ports, to meet the production quantities of customers with various sizes of products.

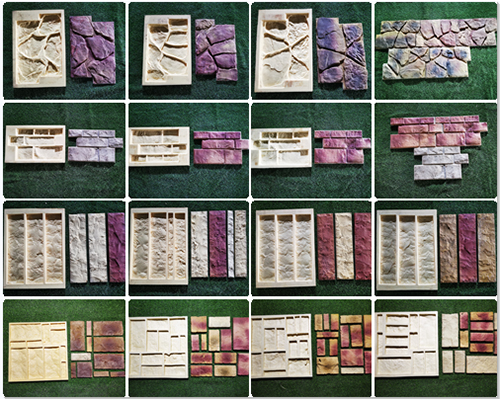

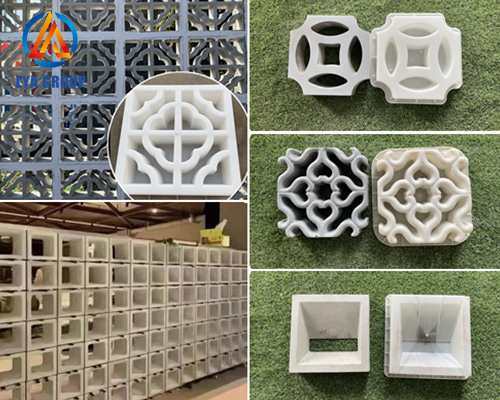

2.Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .

3.The cultural stone production line relates to the technical field of artificial stone production, and discloses an artificial cultural stone mold turning device, comprising a first conveying platform and a second conveying platform arranged in parallel, and a turning frame is arranged between the first conveying platform and the second conveying platform, A clamping mechanism is arranged in the overturning frame, the end of the overturning frame is provided with a holding mechanism corresponding to the clamping mechanism, and the second conveying platform includes a material receiving and conveying mechanism corresponding to the overturning frame and the clamping mechanism.

4.The mold is turned over from one conveying platform to another conveying platform through the turning frame, so as to realize the turning of the mold and prepare for the subsequent demoulding. The structure is simple, the turning efficiency is high, and it can be effectively combined with the subsequent demoulding process. , greatly improving the production efficiency, strong practicability and good use effect.

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/600-800 |

| Weight(Kg) | 2000/1500 |

Auto Dosing Machine

It include the mixing hopper, concrete doser with pneumatic control and storage silo;

The bright spot

1.concrete dosing can be calculated kilograms, not by time; thus to keep the dosing in a more accurate way.

2.Pneumatic door switching design, not wasting any more concrete for each dosing.

3.Adopt the storage silo for saving the concrete from each dosing, can save up to 75kg each time.

4.It has vibration function assembled with the dosing part, after dosing the concrete on the molds then will start vibration.

5.Digital screen controller, with all dosing weight available by only setting up the button ,it is fully automatic mode.

6.Save 6-8 labors for the factory, and reduce the working strength of the labors.

7.Adopt the frequency motor, all size of raw material will not stuck at the mixing & dosing process. make sure machine parts will long lasting use and power saving.

Auto Screen controller

Assemble the motor frequency converter, Siemens unit, power switch supply, and software.

1.Transfer the suitable power signal to the motor, then the motor will run in a smooth way and no harm to the motor itself.

2.Set up the concrete dosing quantity according to the molds required, no more no less, 100% accurate dosing.

3.Assemble all the production line parts together, all controlled by this one cabinet, all parts machine will be more smooth running.

4.System error alert function available, when there is error running problem, the all system power will cut and can track where the problem is from the cabinet screen.

5.Frequency adjustable:10-60HZ;Voltage adjustable:380-440V Power adjustable:20-150KW.