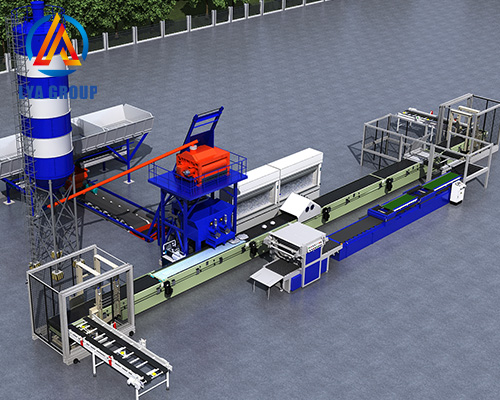

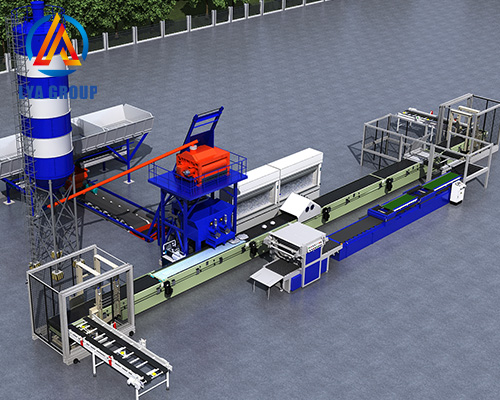

Precast automatic wet casting doser machine paver making machine

Enquiry Email: harvey_lya@zzlya.com

Product Description 1.wet casting doser machine relates to the technical field of artificial stone production, and discloses an artificial cultural stone mold turning device, comprising ŌĆ”ŌĆ”

Introduction

Product Description

1.wet casting doser machine relates to the technical field of artificial stone production, and discloses an artificial cultural stone mold turning device, comprising a first conveying platform and a second conveying platform arranged in parallel, and a turning frame is arranged between the first conveying platform and the second conveying platform, A clamping mechanism is arranged in the overturning frame, the end of the overturning frame is provided with a holding mechanism corresponding to the clamping mechanism, and the second conveying platform includes a material receiving and conveying mechanism corresponding to the overturning frame and the clamping mechanism.

2.The mold is turned over from one conveying platform to another conveying platform through the turning frame, so as to realize the turning of the mold and prepare for the subsequent demoulding. The structure is simple, the turning efficiency is high, and it can be effectively combined with the subsequent demoulding process. , greatly improving the production efficiency, strong practicability and good use effect.

Wet casting doser machine specification:

1. Advanced technology. Fully automatic artificial stone production line, using German technology, can produce various types of artificial stone designs, making production faster and easier.

2. High quality. Quality is our culture. We have established more than 35 production lines around the world.

3. High output, more convenient and faster, and labor saving. All production lines only need 5-6 workers, and the daily production capacity exceeds 1000M2.

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/600-800 |

| Weight(Kg) | 2000/1500 |