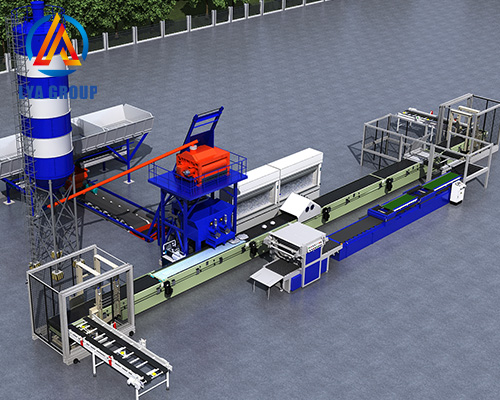

Wall panel production line for concrete wet cast mould turnover wet doser machine

Enquiry Email: harvey_lya@zzlya.com

Product Description Concrete wet cast mould turnover wet doser machine is a type of equipment used in the production of concrete products through the wet cast method. This machine combinŌĆ”ŌĆ”

Introduction

Product Description

Concrete wet cast mould turnover wet doser machine is a type of equipment used in the production of concrete products through the wet cast method. This machine combines two important functions: mould turnover and dosing.

Mould turnover is the process of rotating the mould to allow for the removal of the cast product. It is an essential step in the wet cast process, as it ensures that the cast product is not damaged during removal. The mould turnover function of the machine is achieved through the use of hydraulic cylinders, which rotate the mould to the desired position.

Overall, the concrete wet cast mould turnover wet doser machine is an important tool in the concrete production industry, as it allows for the efficient and consistent production of high-quality concrete products.

Wall panel production line product details:

1. More efficient production, can achieve 800M2 Per day (8hrs) ŌĆó

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/600-800 |

| Weight(Kg) | 2000/1500 |

Main Features

Application