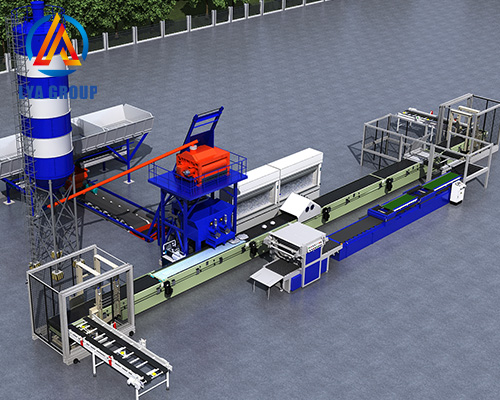

Automatic casting wet doser Plastic artificial stone bricks manufacture line

Enquiry Email: harvey_lya@zzlya.com

Product DescriptionAutomatic casting wet doser production line,is specialized in producing different size of interlock blocks,adopt Square recycling design,pallet keep no moving,can be singŌĆ”ŌĆ”

Introduction

Product Description

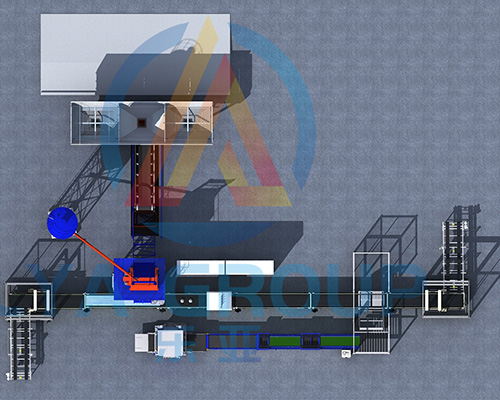

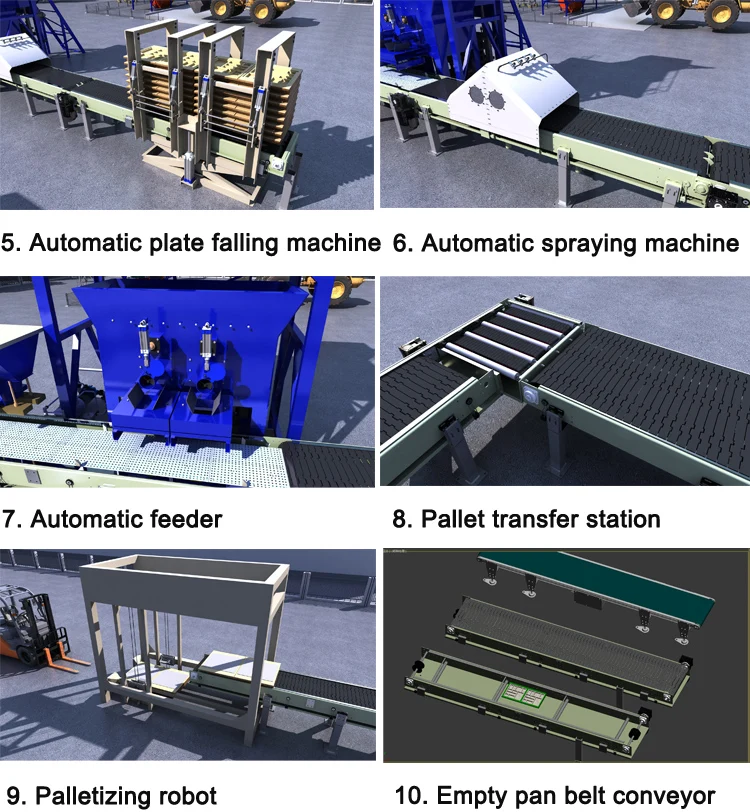

Automatic casting wet doser production line,is specialized in producing different size of interlock blocks,adopt Square recycling design,pallet keep no moving,can be single working line and double working line with daily capacity 9000-18000pcs,available size from 400*100*200mm,400*200*200mm,400*150*200mm,300*150*150mm,600*150*250mm and its half mold available,can cast 4 piece blocks each time,and can adjust according to the different requirements. it is weight casting with pneumatic control,also with function of auto releasing oil painting,auto stacking and unstacking machine ,all the equipment is designed separately,customer can one each part only or can assemble them together be complete production line.

Automatic casting wet doser production line Product Details:

1. More efficient production, can achieve 800M2 Per day (8hrs) ŌĆó

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

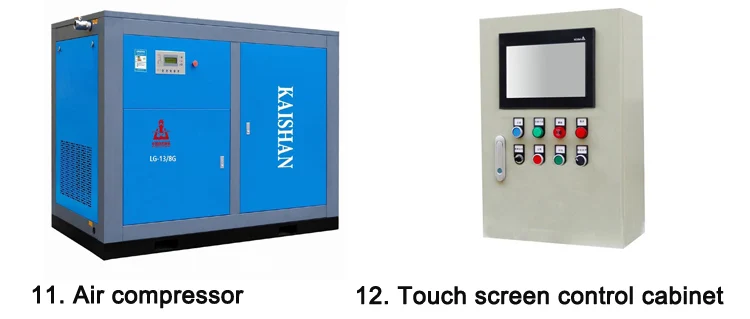

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

Related Products