Manufacture machine artificial veneer stone production line wet casting doser machine

Enquiry Email: harvey_lya@zzlya.com

Product Description 1.Wet casting doser machine is a type of equipment used in the production of concrete products through the wet cast method. The wet cast method involves mixing cŌĆ”ŌĆ”

Introduction

Product Description

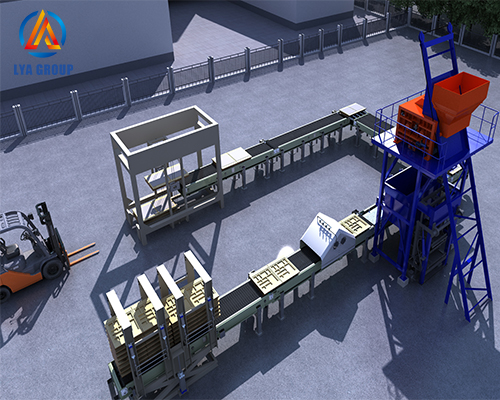

1.Wet casting doser machine is a type of equipment used in the production of concrete products through the wet cast method. The wet cast method involves mixing concrete with water and pouring it into a mold, which is then vibrated to ensure proper compaction and distribution of the concrete.

2.The wet casting doser machine is designed to automate the process of dispensing the wet concrete mixture into the mold. It typically consists of a hopper, a dosing system, and a control system. The hopper is used to hold the wet concrete mixture, while the dosing system accurately measures and dispenses the mixture into the mold. The control system ensures that the mixture is dispensed at the correct rate and in the correct amount.

3.The use of a wet casting doser machine increases production efficiency and reduces labor costs. It also ensures that the concrete mixture is dispensed consistently, resulting in high-quality concrete products.

Wet casting doser machine product details:

1. More efficient production, can achieve 800M2 Per day (8hrs) ŌĆó

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

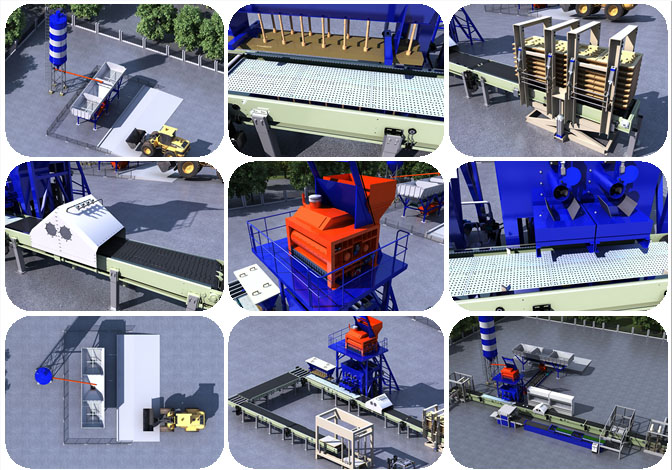

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/600-800 |

| Weight(Kg) | 2000/1500 |

Related Products