Concrete artificial stones production line wet casting doser machine

Enquiry Email: harvey_lya@zzlya.com

Product DescriptionWet cast pavers typically tend to be more expensive than dry cast. For projects with budget restraints, dry cast pavers will most likely be the more economical option. WeŌĆ”ŌĆ”

Introduction

Product Description

Wet cast pavers typically tend to be more expensive than dry cast. For projects with budget restraints, dry cast pavers will most likely be the more economical option. Wet cast pavers appear to have a smooth non-porous surface while dry cast pavers visibly look to have a rougher, more porous surface.

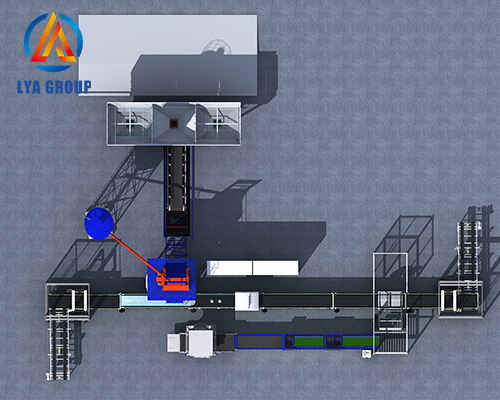

The overall batching system adopts batching machine, cement silo, JS500 mixer (JS750 can be replaced if the customer needs large output), equipped with water scale, cement scale and PLC control cabinet. For example, the mobile clear equipment of the mixer can be added to the quotation at the high-end end of the system, and the batching machine can be replaced with a single warehouse and weighed separately.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 800-1000 | 2000 |

Main Features

Application