What is the advantagesartificial stones feeding machine line production’╝¤

News 2022Õ╣┤7µ£ł27µŚź 237

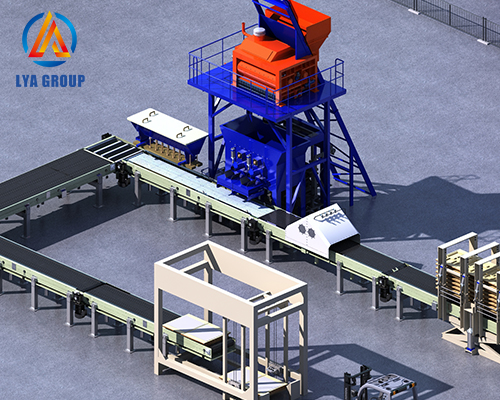

Specializing in the manufacture of fully automatic artificial stone feeding machine production line for more than ten years, which can be customized according to customer requirements(the size of the factory, size of the molds and shape of the molds), it is suitable for all kinds of precast concrete molds of different quality,different specifications and different shapes of cultural stone, wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .From formulated raw materials to demoulding and packaging. All can be automated, save time and effort.

According to the requirements of the customer’s site, the length of precast concrete production lines can be customized, and the output can be controlled. At least 800 square meters can be produced per day, saving labor. The complete production line only needs 5-6 workers, and only needs to be responsible for controlling the cabinet of the machine, simple and easy;

The precast concrete production line making machine is divided into 15 parts from ingredients to packaging, which are connected and operated through a programmable control cabinet, each part and half part can work independently.

All the parts include cement silo, batching machine,Auto Concrete forced Mixer,auto unloading machine , auto pallet turning machine,Auto Spray Machine’╝īconcrete filling machine’╝īauto stacking machine,auto packing machine,auto demoulding machine,auto vibration part’╝īHydraulic conveyor’╝īAir compressor,auto screen controller ’╝īdust collecting machine.

Let’s learn the function of each part of paving block artificial stone production line’╝ÜThe cement silo, used to stock the cement in the tank and ship the cement powder to the batching machine as required quantity. As for artificial stone producing capacity, the 30T model is the suitable one. The batching machine save three different material ,cement, ceramsite and the aggregate particles, and dosing these raw material by a confirmed & accurate ratio. then transport the mixed raw material to the concrete mixer.