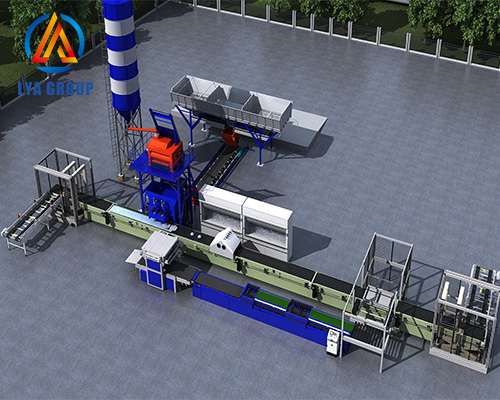

Concrete Automatic artificial Production Line feeder concrete dosing system

Enquiry Email: harvey_lya@zzlya.com

feeder concrete dosing system, also known as a concrete batching plant or concrete mixing plant, is a device used in construction to accurately measure and combine various ingredients to prŌĆ”ŌĆ”

Introduction

feeder concrete dosing system, also known as a concrete batching plant or concrete mixing plant, is a device used in construction to accurately measure and combine various ingredients to produce concrete. These systems are designed to automate the process of batching and mixing concrete, ensuring consistency and efficiency in concrete production.Feeder concrete dosing systems can vary in terms of capacity, automation level, and mobility. They can be stationary, semi-mobile, or fully mobile, depending on the specific requirements of the construction project. Some systems are equipped with additional features, such as automatic moisture control or integrated data logging for quality control purposes.It’s worth noting that there are various types of concrete dosing systems available, such as batch plants, continuous mixers, or volumetric mixers. Each type has its own advantages and suitability for different applications. Consulting with suppliers or manufacturers specializing in concrete batching equipment can provide more detailed information and guidance on selecting the appropriate feeder concrete dosing system for specific construction needs.

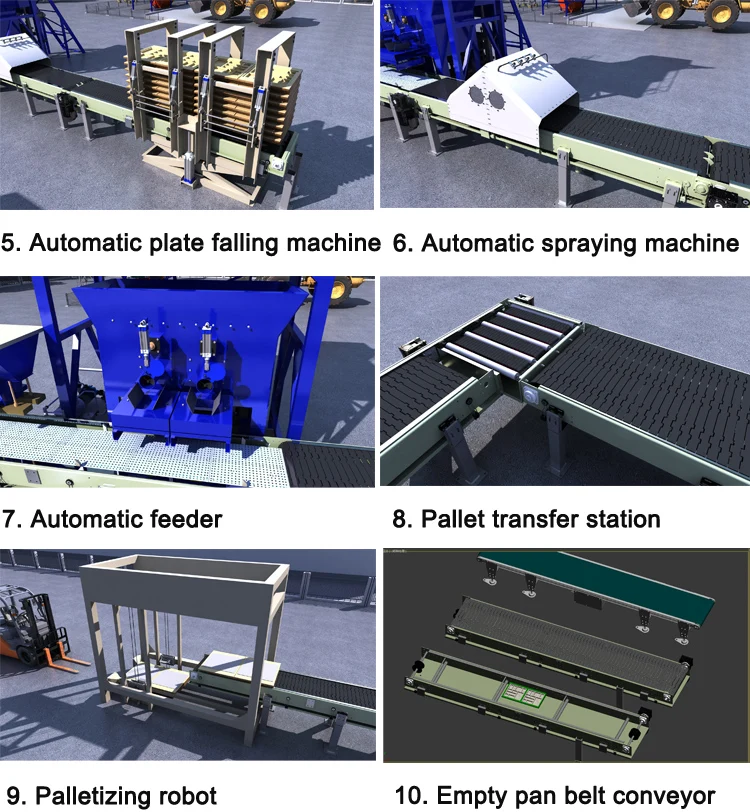

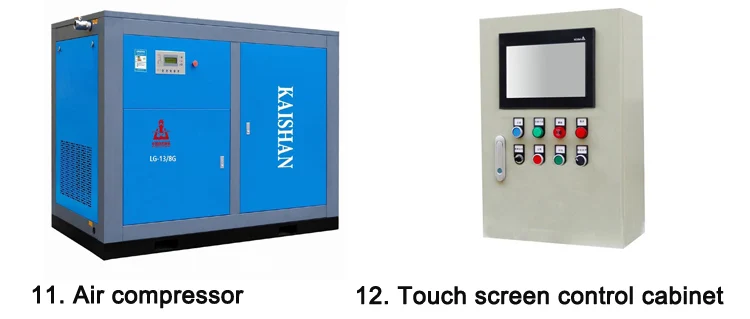

Product Details:

1. More efficient production, can achieve 800M2 Per day (8hrs) ŌĆó

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Application:

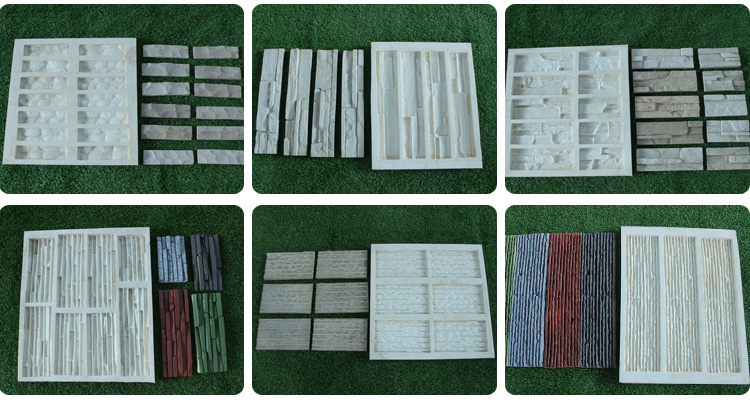

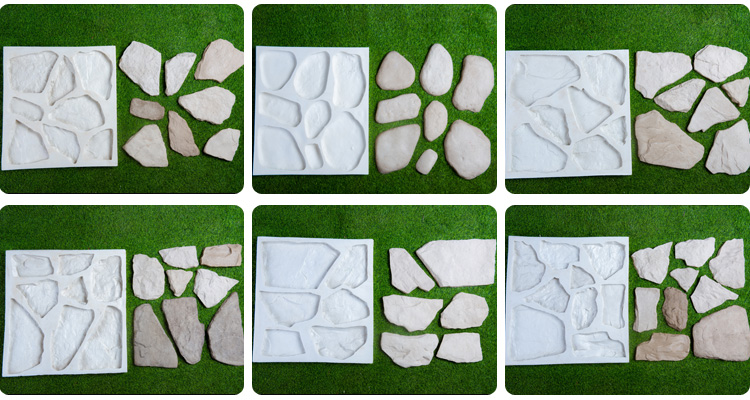

Also we have many kinds of designs silicon mould for make artificial stone.The silicon moulds are very durable.Each mould can be used 2000 times at least.The molds standard dimension is 560X560X45mm, weight 7.5kg one piece.Artificial Stone has become an appreciated artwork to some extent. Types of brick face for natural-like series are imitated slad, imitated sandstone, imitated serpeggiante, etc.

Our Certificate: