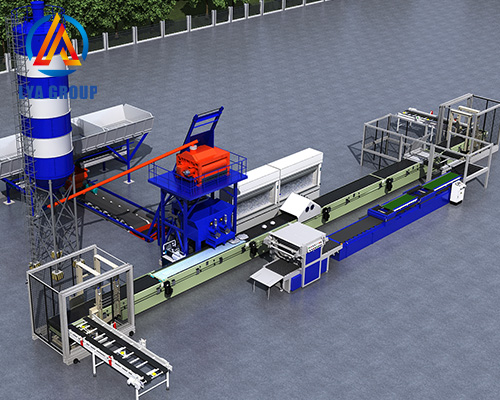

Full-Automatic Engineering Square Stone clay artificial stone production line

Enquiry Email: harvey_lya@zzlya.com

1.More efficient production,can achieve 800M2 Per day(8hrs)2.Labors saving for production,5-6 workers needed only,can largely reduce the labor cost of factory output.3.Multiple function forŌĆ”ŌĆ”

Introduction

1.More efficient production,can achieve 800M2 Per day(8hrs)

2.Labors saving for production,5-6 workers needed only,can largely reduce the labor cost of factory output.

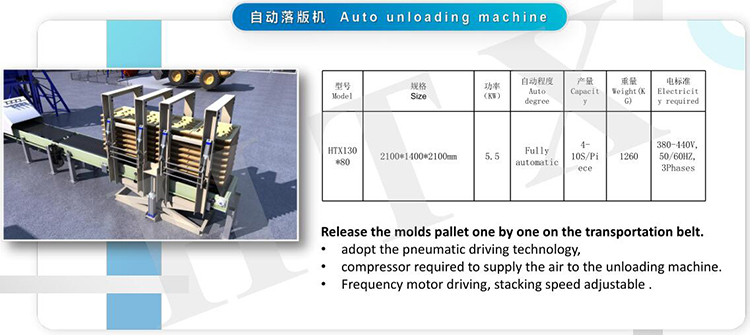

3.Multiple function for production,it include unloading,painting ,concrete dosing and stacking ,and available usage for plastic molds of floor tile and terrazzo tile,silicone molds for artificial stone etc.

4.The auto spray painting machine,has function for mold oil painting,stroll color painting and full color painting,also it can be turned on/off separately.

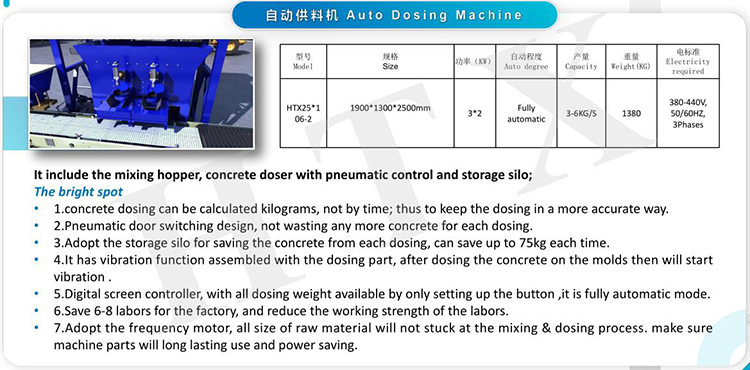

Concrete dosing system artificial stone production line,adopt technoligly of automatic color pating,concrete adding ,vibrating and tranporting.

It largely reduce the manpower used and imporve the efficiency.

Additionally,we install 12 pieces airbrush inside machine,and can spray 4 colors at one time.

It keep spraying during the silicon moulds moving on the convey belt,thus the final stone will have a gradually varied color.

The stone will own a unique color which will be more popular in the market.

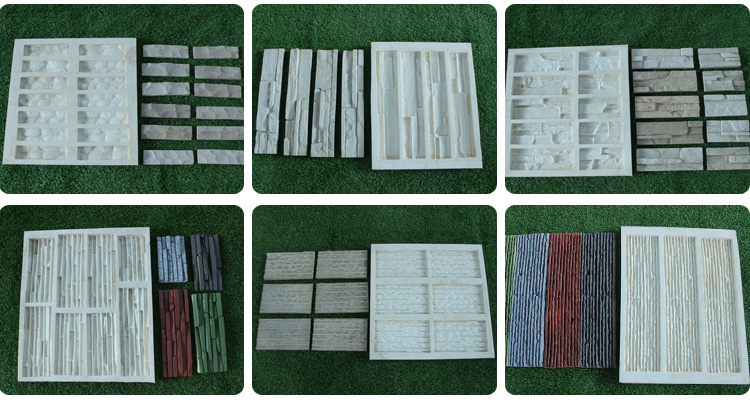

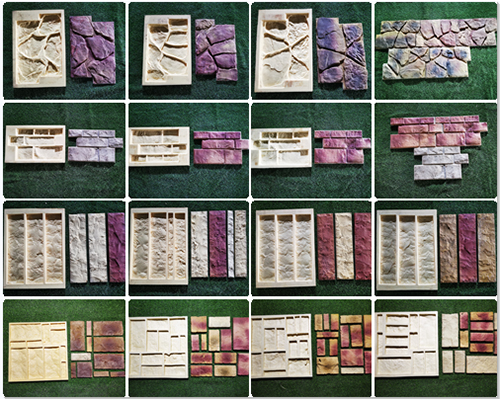

Also we have many kinds of designs silicon mould for make artificial stone.The silicon moulds are very durable.Each mould can be used 2000 times at least.Here are some cultural stone molds. If you are interested, we can send you relevant catalogs and more styles