Veneer artificial stone making manufacture line automatic wet cast dosing system

Enquiry Email: harvey_lya@zzlya.com

Product Description Automatic wet cast dosing system main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking mŌĆ”ŌĆ”

Introduction

Product Description

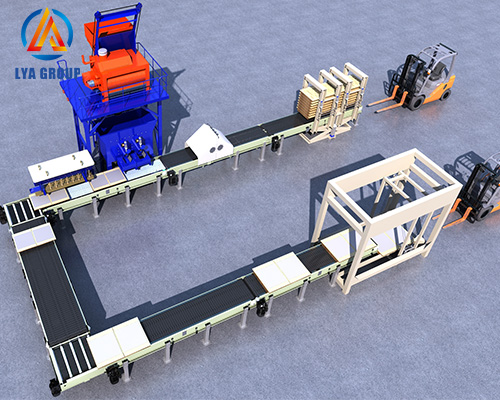

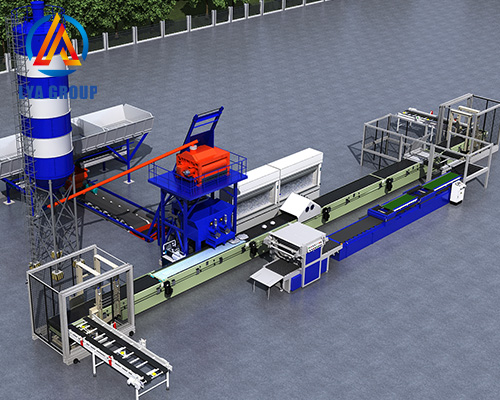

Automatic wet cast dosing system main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking machine, auto spary machine(used for add color for veneer stone), auto demolding machine, finished culture stone drying, and so on. In a whole word, from material to finished artificial stone package all full auto.

Concrete casting wet doser machine Product Details ’╝ÜMore efficient production, can achieve 800M2 Per day (8hrs)’╝īMultiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

Paremeter

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding;vibrating and timing feeding | 7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

Related Products