High efficiency fully automatic terrazzo artificial stone production line for sale

Enquiry Email: harvey_lya@zzlya.com

Product Description With the full auto indoor cultured stone production line, the veneer stone manufacturer can save a lot of labor cost and can Increase productivity. More over, it can ŌĆ”ŌĆ”

Introduction

Product Description

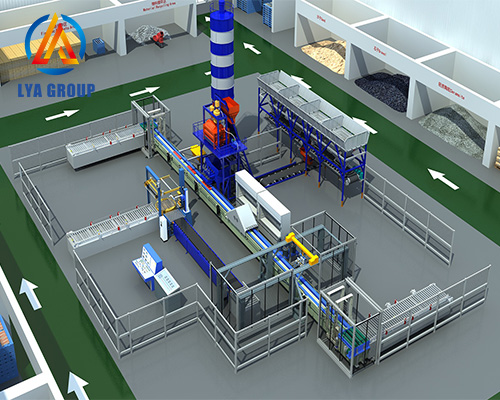

With the full auto indoor cultured stone production line, the veneer stone manufacturer can save a lot of labor cost and can Increase productivity. More over, it can achieve collect dust in the workplace to protect environment, and also can demold automatically, this is a new progress during veneer stone production.

The full auto veneer stone production line include cement silo, batching machine, and forced auto mixer. The cement silo need equipped with a screw feeder. To delivery cement into mixer. The batching machine have two or three hoppers. And have weighted function at bottom of each hopper. All the three machines need a PLC controller to control each function. Then come to dosing part, spraying part. The dosing part feed material by weight and time, and equipped with conveyor and vibration point. The spraying part can remove dust and spray demold oil or spray color. The dosing part also have touch screen PLC controller.Other parts are demold machine, unloading and loading machine, package machine, dust clearance machine, and so on. All the system can be customized according to clients requirements for cladding stone.

Paremeter

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

Related Products