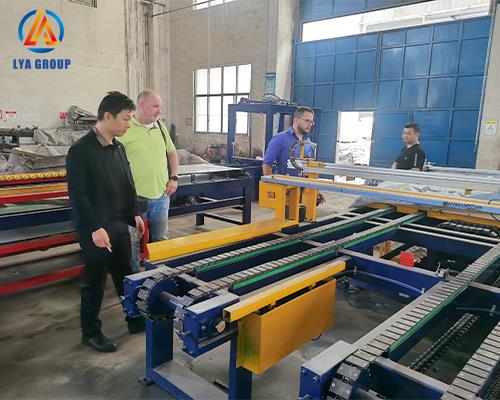

Fully automatic wet material pouring production line

News 2024Õ╣┤12µ£ł18µŚź 100

The fully automatic wet material pouring production line is an equipment system used to produce concrete products. It realizes the entire process control of pouring and forming wet concrete through automation technology and mechanized operation.

The production line usually includes the following main components:

Concrete mixer: used to mix water, cement, sand, aggregate and other raw materials to form wet materials.

Conveying system: Conveys wet concrete from the mixer to the pouring area. This may include conveyor belts, augers, or other types of conveying equipment.

Pouring robot or device: used to accurately pour wet materials onto molds or work surfaces. These robots or devices usually have precise motion control systems and can perform pouring on molds of different sizes and shapes.

Mold system: used to contain wet materials and form the final product. Molds can be pre-made, reusable or single-use, depending on the product type and production needs.

Control system: used to monitor and control the operation of the entire production line. This includes automated control systems, sensors, computer interfaces and other related equipment.

Cleaning and maintenance system: used to clean and maintain equipment to ensure the normal operation and good working condition of the production line.

The advantages of a fully automated wet pouring production line include increased production efficiency, reduced labor costs, reduced human errors and improved product quality consistency. It can be widely used in the construction industry to produce various concrete products such as concrete wall panels, floor tiles, pipes, walls, and slope protection.

It should be noted that the specific fully automatic wet pouring production line may vary depending on the manufacturer and product needs, and the above description only provides a general overview. In actual applications, it also needs to be designed and customized according to specific conditions.