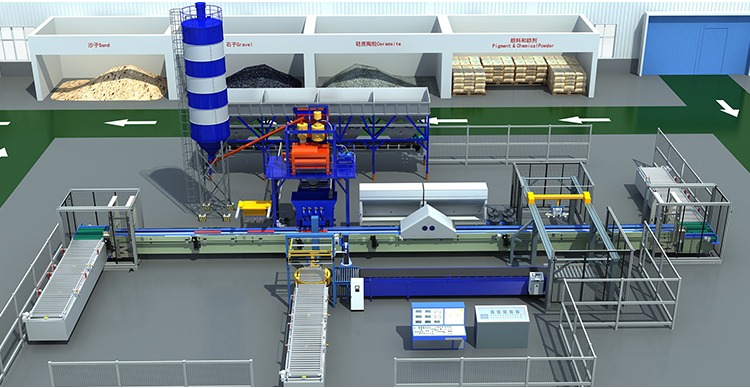

Automatic veneer stone production line Smooth Face Concrete Sleepers machine

Enquiry Email: harvey_lya@zzlya.com

Veneer stone production line refers to a manufacturing process designed to produce veneer stones, which are thin slices or facades ofŌĆ”ŌĆ”

Introduction

Veneer stone production line refers to a manufacturing process designed to produce veneer stones, which are thin slices or facades of stone used to give the appearance of natural stone to various surfaces. These surfaces can include walls, fireplaces, pillars, and other architectural elements. It’s important to note that the exact production line setup and processes can vary depending on the specific manufacturer and their equipment. Advanced production lines may incorporate automated machinery and robotics for increased efficiency and consistency.

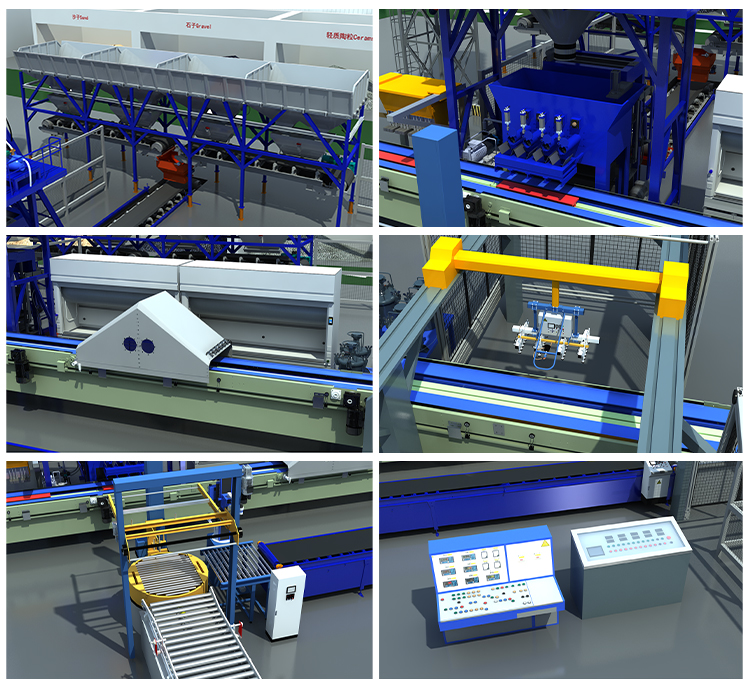

Specification:

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding/Chain drived;Auto feeding,auto vibration |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/800-1000 |

| Weight(Kg) | 2000/1500 |

Applications

Wet cast machinery, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for paving tile molds, 3D wall molds, concrete sleeper molds , Fence Panel molds, Wall panel molds, roadside stone molds, retaining wall molds, wall cap molds, etc.