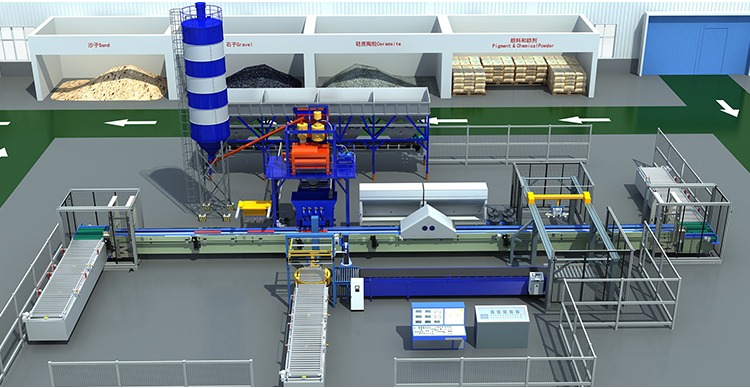

High Productivity Concrete Fence Panel making machine cladding┬Āpanel production line

Fence panel machine 2024Õ╣┤4µ£ł17µŚź 235

Concrete fence panel making machine is a specialized machine used for the manufacturing of concrete fence panels. These panels are commonly used in various applications, such as residential, commercial, and industrial fencing, providing security, privacy, and aesthetic appeal.It’s important to note that the specific design and features of a concrete fence panel making machine can vary depending on the manufacturer and the desired production capacity. These machines are typically designed to optimize productivity, quality, and safety while minimizing manual labor and production time.

Here is an overview of the key components and processes involved in a typical concrete fence panel making machine:

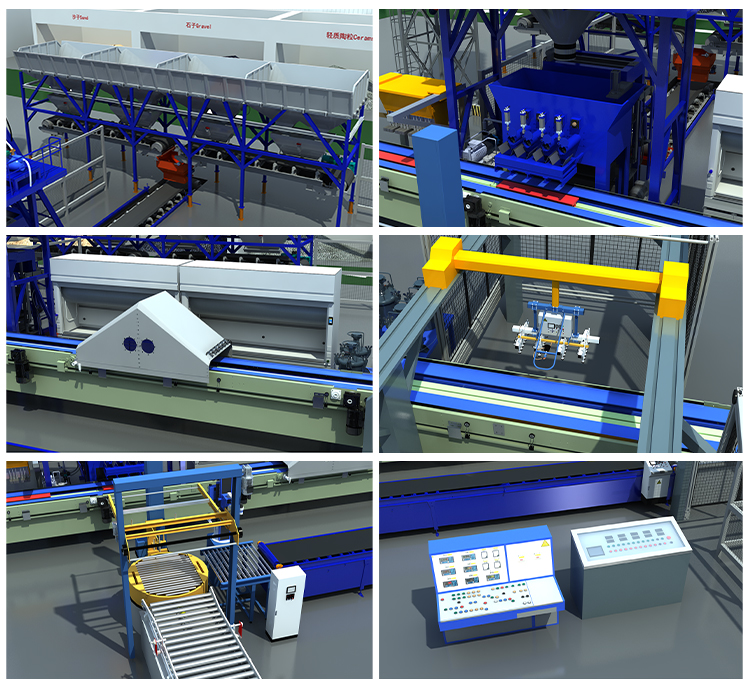

- Concrete Mixing: The machine is equipped with a concrete mixer or batching plant that automatically mixes the required proportions of cement, aggregates (such as sand and gravel), water, and additives to produce the concrete mixture. The mixture is usually blended to a specific consistency suitable for molding.

- Molding System: The machine has a set of molds or formwork designed to shape the concrete into fence panels. The molds can have various designs and sizes, depending on the desired type and style of the fence panel. The molds are prepared by applying a release agent to facilitate easy removal of the panels once they are cured.

- Concrete Pouring: The prepared concrete mixture is poured into the molds using an automated pouring system. The pouring process ensures that the concrete is evenly distributed within the molds and fills all the required sections and patterns.

- Compaction: After pouring, the machine applies vibration or pressure to the molds to compact the concrete and remove any air voids. This ensures the structural integrity of the fence panels and reduces the risk of cracking or other defects.

- Curing: The compacted concrete-filled molds are transferred to a curing chamber or area where they are kept under controlled conditions (such as temperature and humidity) for a specific duration. This allows the concrete to gain sufficient strength and durability. Curing can be done through natural processes or accelerated curing methods, depending on the requirements.

- Demolding: Once the curing period is complete, the machine automatically demolds the cured fence panels from the molds. This can be done using mechanical systems or hydraulic mechanisms that gently release the panels without causing any damage.

- Finishing: The demolded fence panels may undergo additional finishing processes, such as surface cleaning, trimming of excess material, and application of desired textures or patterns. These processes enhance the appearance and functionality of the panels.

- Stacking and Packaging: The finished concrete fence panels are stacked and packaged automatically, ready for transportation and installation at the desired locations. Advanced machines may incorporate robotic systems for efficient handling and stacking.

Specification:

| Name | Wet Cast Machinery |

| Model | HTX-P-01/HTX-P-02 |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding/Chain drived;Auto feeding,auto vibration |

| Size(mm) | 7000*1000*1800/8000*1100*1600 |

| Power(Kw) | 12.7/4.05 |

| Capacity(m2/day) | 1000-1500/800-1000 |

| Weight(Kg) | 2000/1500 |

Applications

Wet cast machinery, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for paving tile molds, 3D wall molds, concrete sleeper molds , Fence Panel molds, Wall panel molds, roadside stone molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include:

1.On-site technical support and maintenance

2.Expert assistance with installation and setup

3.Remote and telephone troubleshooting and support

4.Periodic maintenance and inspection

5.Repair and replacement parts

6.Technical training and user manuals

7.Upgrades and software updates