Breeze block making machines

News 2024ŚĻī2śúą17śó• 157

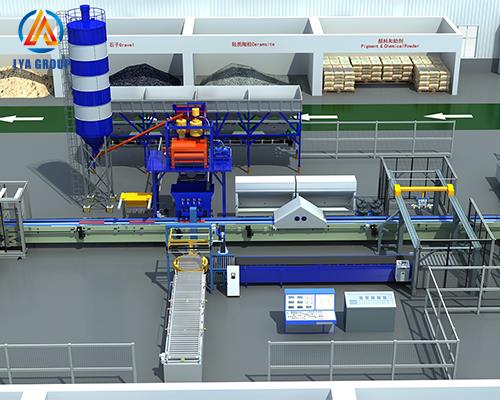

Breeze blocks, also known as concrete blocks or cinder blocks, are commonly used in construction for walls, partitions, and other structural elements. Breeze block making machines are specialized machines used to manufacture breeze blocks in a factory or production setting. These machines automate the process of molding and curing concrete blocks, increasing efficiency and consistency. Here are the key components and processes typically involved in a breeze block making machine:

Raw material preparation: The production process starts with the preparation of the raw materials. This typically involves mixing cement, aggregates (such as sand or crushed stone), and water to create a concrete mixture. The proportions of the ingredients are carefully controlled to ensure the desired strength and consistency of the breeze blocks.

Molding: The concrete mixture is transferred to the breeze block making machine, which includes a mold or formwork for shaping the blocks. The mold is typically made of steel and has cavities in the shape and size of the breeze blocks. The concrete mixture is poured into the mold, and the machine applies pressure and vibration to compact the mixture and remove any air voids.

Curing: After molding, the blocks undergo a curing process to gain sufficient strength. Curing can be done through various methods, such as steam curing, water curing, or air curing. The blocks are typically kept in a controlled environment for a specified period to allow the concrete to hydrate and harden properly.

Demolding: Once the blocks have cured and reached the desired strength, they are demolded from the molds. This can be done manually or with the help of demolding equipment integrated into the breeze block making machine. The demolding process should be carefully executed to ensure the blocks are not damaged or deformed during removal from the molds.

Finishing: After demolding, the blocks may undergo additional finishing processes to achieve the desired appearance and surface characteristics. This can include processes such as grinding, chamfering, or surface coating to enhance the aesthetic appeal and functionality of the blocks.

Quality control: Throughout the production process, quality control measures are implemented to ensure that the breeze blocks meet the required specifications and standards. This can involve regular testing of the concrete mixture, dimensional checks of the blocks, and visual inspections for any defects or imperfections.

Stacking and packaging: Once the blocks have been inspected and approved, they are typically stacked and packaged for storage or transportation. Stacking can be done manually or with the assistance of automated stacking equipment. Packaging methods may vary depending on the specific requirements and market preferences, but common practices include palletizing or bundling the blocks.

Automation and control: Breeze block making machines are often equipped with automation and control systems to manage and monitor the entire production process. This includes controlling the flow of materials, adjusting machine parameters, tracking production data, and ensuring safety measures are in place.