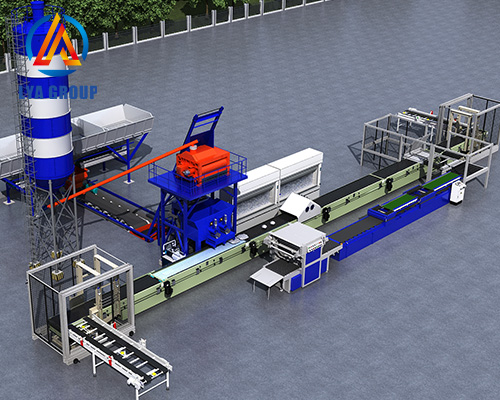

Artificial stone mold brick semi-automatic production line

News 2023Õ╣┤10µ£ł25µŚź 238

An artificial stone mold brick semi-automatic production line typically refers to a production system or process that involves the semi-automatic manufacturing of artificial stone bricks using molds. Here’s a general overview of the components and steps involved in such a production line:

1.Mixing and Preparation: The production process usually begins with the preparation of the raw materials. This may involve mixing cement, aggregates, pigments, and other additives in specific proportions to create the artificial stone mixture. The mixture is typically prepared in a concrete mixer or a specialized mixing machine.

2.Mold Preparation: The artificial stone molds are prepared for casting. The molds, which are designed to create the desired brick shape, are cleaned, inspected for any defects, and coated with a release agent to facilitate demolding.

3.Mold Filling: In the semi-automatic production line, the mold filling process is typically done manually or with the assistance of a machine. The artificial stone mixture is poured or placed into the mold cavities, ensuring that each cavity is filled evenly.

4.Compaction and Vibration: Once the mold is filled, the artificial stone mixture may undergo compaction and vibration to remove air bubbles and ensure proper consolidation. This can be done using a vibrating table or a compaction machine.

5.Curing: After compaction, the filled molds are typically left to cure and harden. The curing process may involve keeping the molds in a controlled environment with appropriate temperature and humidity conditions. The duration of curing can vary depending on the specific type of artificial stone being produced.

6.Demolding: Once the artificial stone bricks have sufficiently cured and hardened, the molds are opened, and the bricks are carefully demolded. This step may require manual handling or the use of demolding equipment.

7.Finishing and Quality Control: After demolding, the artificial stone bricks may undergo additional finishing processes, such as trimming or polishing, to achieve the desired appearance and quality. The bricks are inspected for any defects or imperfections and sorted according to quality standards.

8.Packaging and Storage: The final step in the production line involves packaging the artificial stone bricks for transportation and storage. The bricks may be stacked, palletized, and wrapped for protection.

It’s important to note that the specific equipment, machinery, and processes involved in a semi-automatic production line can vary depending on the manufacturer and the scale of production. The line may also incorporate automation to varying degrees, with certain steps being automated while others require manual intervention.