Semi automatic concrete paver block machine

Enquiry Email: harvey_lya@zzlya.com

Semi automatic concrete interlocking paver block machine is a type of machinery used in the construction industry to produce interlocking concrete or cement paver blocks. These blocks are commonlŌĆ”ŌĆ”

Introduction

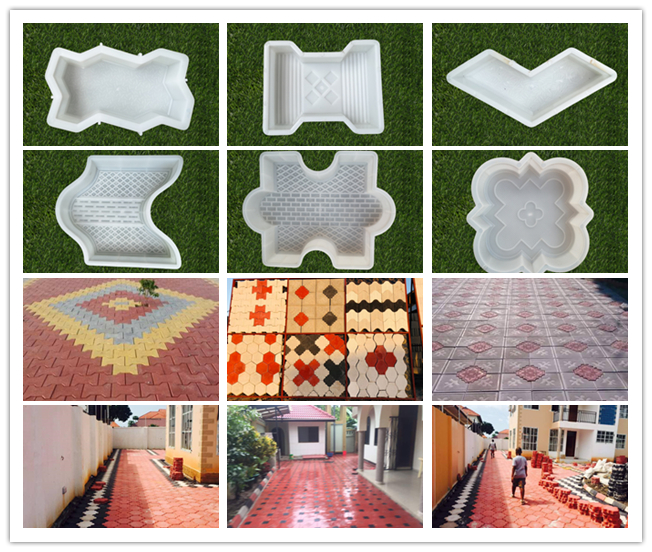

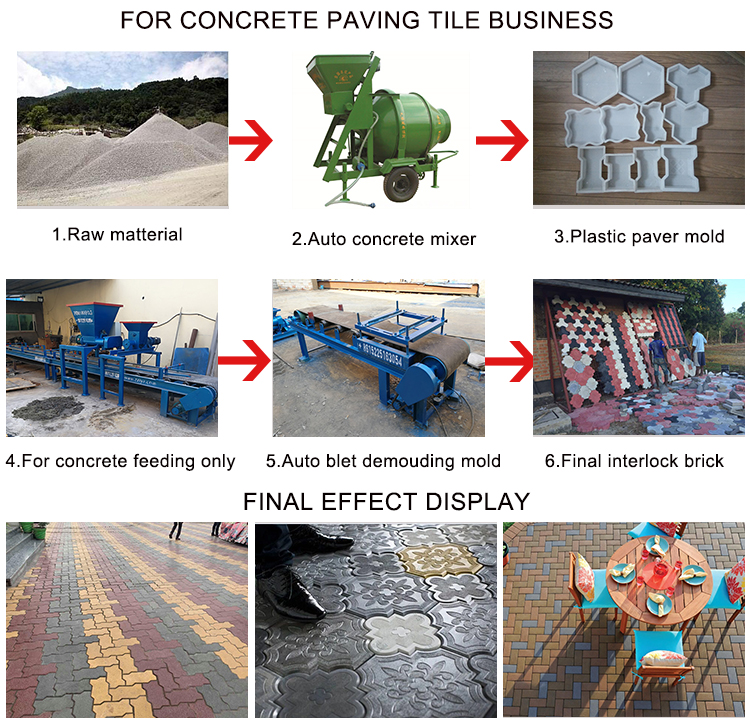

Semi automatic concrete interlocking paver block machine is a type of machinery used in the construction industry to produce interlocking concrete or cement paver blocks. These blocks are commonly used for paving driveways, walkways, patios, and other outdoor surfaces.

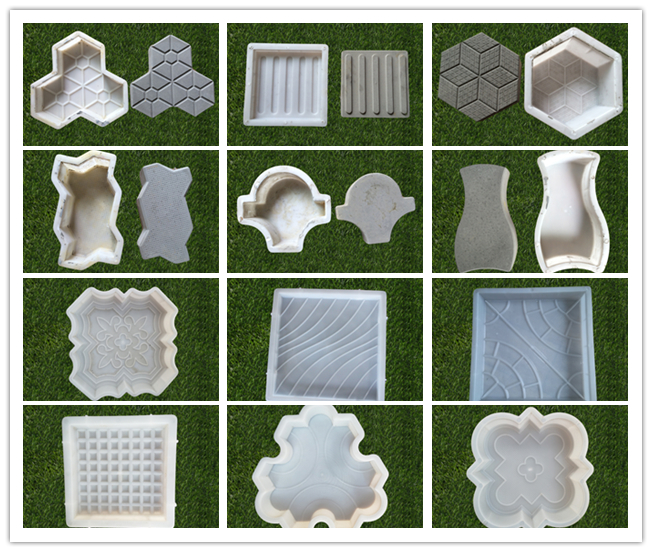

The machine typically consists of a mold or a set of molds that shape the paver blocks, a hydraulic system that applies pressure to the molds, and a conveyor or pallet system that transports the finished blocks for curing and storage. The specific design and features of the machine may vary depending on the manufacturer and model.

When considering an interlocking paver block machine, it’s important to research reputable manufacturers, compare features and specifications, and consider factors such as production capacity, power requirements, and maintenance needs. Additionally, local regulations and standards related to paver block production should be considered to ensure compliance with quality and safety requirements.

| Capacity | 2000-2500 Blocks per hour |

| Method | Vibration process |

| Automation Grade | Semi-Automatic |

| Minimum Order Quantity | 1 Set |

| Automation Grade-HTX | Auto-Automatic |

Video of producing concrete paver block

Our company has fully automatic floor tile production equipment, and more efficient production of floor tiles can help save labor and help people produce faster to a greater extent.fully automatic paving block machine is a type of machinery used in the construction industry to produce paving blocks or bricks in an automated manner. It is designed to streamline the block production process and minimize manual labor.When considering a fully automatic paving block machine, it’s essential to research reputable manufacturers, compare models based on production capacity, power requirements, and features like mold interchangeability and maintenance needs. Additionally, consider factors like local regulations, raw material availability, and market demand for specific block designs to make an informed decision.