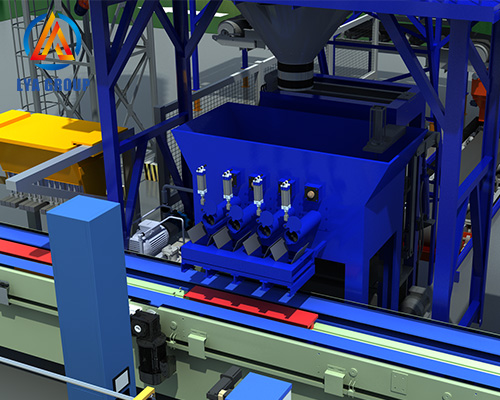

Wet Cast Machinery-Auto Dosing Machine

Enquiry Email: harvey_lya@zzlya.com

It include the mixing hopper, concrete doser with pneumatic control and storage silo; The bright spot 1. concrete dosing can be calŌĆ”ŌĆ”

Introduction

It include the mixing hopper, concrete doser with pneumatic control and storage silo;

The bright spot

1. concrete dosing can be calculated kilograms, not by time; thus to keep the dosing in a more accurate way.

2. Pneumatic door switching design, not wasting any more concrete for each dosing.

3. Adopt the storage silo for saving the concrete from each dosing, can save up to 75kg each time.

4. It has vibration function assembled with the dosing part, after dosing the concrete on the molds then will start vibration.

5. Digital screen controller, with all dosing weight available by only setting up the button ,it is fully automatic mode.

6. Save 6-8 labors for the factory, and reduce the working strength of the labors.

7. Adopt the frequency motor, all size of raw material will not stuck at the mixing & dosing process. make sure machine parts will long lasting use and power saving.

| Model | Size | ’╝łKW’╝ē | Auto degree | Capacity | Weight(KG) | Electricity required |

| HTX25*106-2 | 1900*1300*2500mm | 3*2 | Fully automatic | 3-6KG/S | 1380 | 380-440V,50/60HZ,3Phases |